Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Send Inquiry

USD 2000 ~ 3000

Brand:ZHICHENGDA

Min. Order:1 Ton

Model No:aluminum sliding door track

Transportation:Ocean,Land,Air,Express

Packaging:1. Composite paper packaging. 2. Shrink film packaging. 3. Packed as your request.

Supply Ability:1500 Ton/Tons per Month

USD 2000 ~ 3000

Brand:ZHICHENGDA

Min. Order:1 Ton

Model No:door and window track

Transportation:Ocean,Land,Air,Express

Packaging:1. Composite paper packaging. 2. Shrink film packaging. 3. Packed as your request.

Supply Ability:1500 Ton/Tons per Month

USD 2000 ~ 3000

Brand:ZHICHENGDA

Min. Order:1 Ton

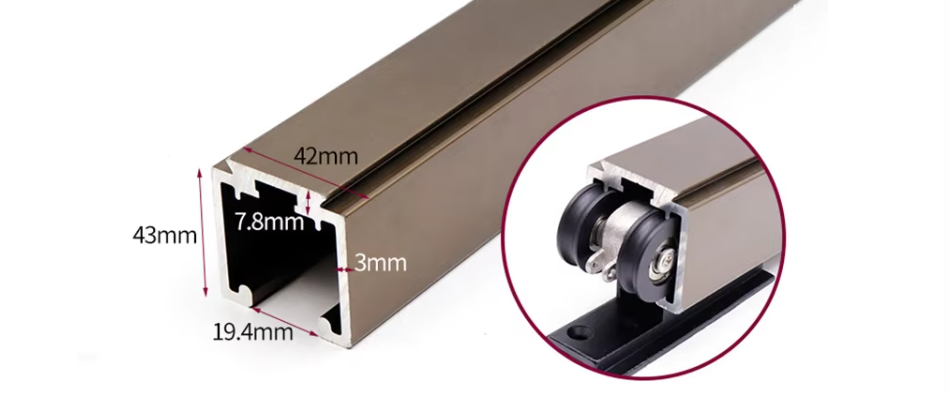

Model No:Wheel Track Aluminium Profile

Transportation:Ocean,Land,Air,Express

Packaging:1. Composite paper packaging. 2. Shrink film packaging. 3. Packed as your request.

Supply Ability:1500 Ton/Tons per Month

USD 2000 ~ 3000

Brand:ZHICHENGDA

Min. Order:1 Ton

Model No:aluminum alloy track wheel

Transportation:Ocean,Land,Air,Express

Packaging:1. Composite paper packaging. 2. Shrink film packaging. 3. Packed as your request.

Supply Ability:1500 Ton/Tons per Month

USD 2000 ~ 3000

Brand:ZHICHENGDA

Min. Order:1 Ton

Model No:Aluminum Track Profile Hardware

Transportation:Ocean,Land,Air,Express

Packaging:1. Composite paper packaging. 2. Shrink film packaging. 3. Packed as your request.

Supply Ability:1500 Ton/Tons per Month

ZHICHENGDA

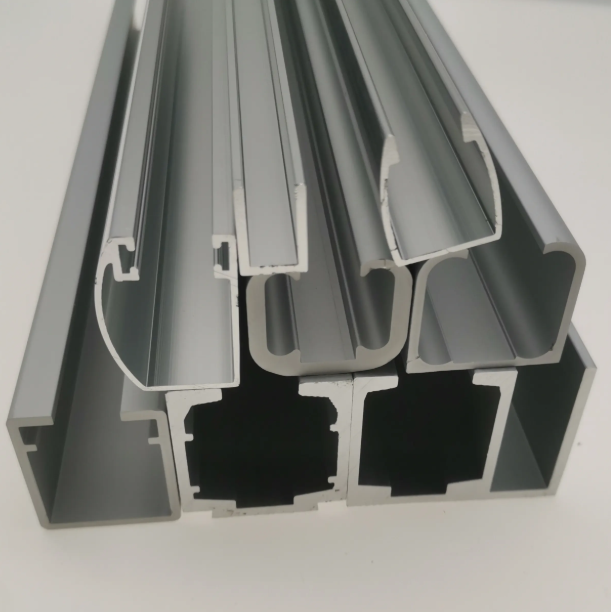

Wheel Rail Aluminum Profiles

Your Better Wheel Rail Aluminum Profiles Manufacturer

ZHICHENGDA factory was established in 2008 and now covers an area of 10,000 square meters. lt has a seriesof complete production equipment and professional R & D teams. The parent companysuccessfully declared as high -tech enterprises in 2021. The products are exported tomany countries and regions at home and abroad.We are committed to providing high-quality products and services, and we look forward to establishing long -term stable co-operative relationships with domestic and foreign business customers.

Copyright © 2025 Gaoyao Jinli Zhichengda Metal Products Factory All rights reserved. Privacy Policy

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.