Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Send Inquiry

USD 2000 ~ 3000

Brand:ZHICHENGDA

Min. Order:1 Ton

Model No:Aluminum Glass Clamp

Transportation:Ocean,Land,Air

Packaging:1. Composite paper packaging. 2. Shrink film packaging. 3. Packed as your request.

Supply Ability:1500 Ton/Tons per Month

USD 2000 ~ 3000

Brand:ZHICHENGDA

Min. Order:1 Ton

Model No:Aluminum profiles for door and window glass clips

Transportation:Ocean,Land,Air

Packaging:1. Composite paper packaging. 2. Shrink film packaging. 3. Packed as your request.

Supply Ability:1500 Ton/Tons per Month

We promise We use China standard aluminum bar Never use recycle or waste aluminum

USD 2000 ~ 3000

Brand:ZHICHENGDA

Min. Order:1 Ton

Model No:Glass Clip Aluminum Profiles

Transportation:Ocean,Land,Air

Packaging:1. Composite paper packaging. 2. Shrink film packaging. 3. Packed as your request.

Supply Ability:1500 Ton/Tons per Month

USD 2000 ~ 3000

Brand:ZHICHENGDA

Min. Order:1 Ton

Model No:partition aluminium panel frame

Transportation:Ocean,Land,Air

Packaging:1. Composite paper packaging. 2. Shrink film packaging. 3. Packed as your request.

Supply Ability:1500 Ton/Tons per Month

USD 2000 ~ 3000

Brand:ZHICHENGDA

Min. Order:1 Ton

Model No:aluminum rail clamp

Transportation:Ocean,Land,Air

Packaging:1. Composite paper packaging. 2. Shrink film packaging. 3. Packed as your request.

Supply Ability:1500 Ton/Tons per Month

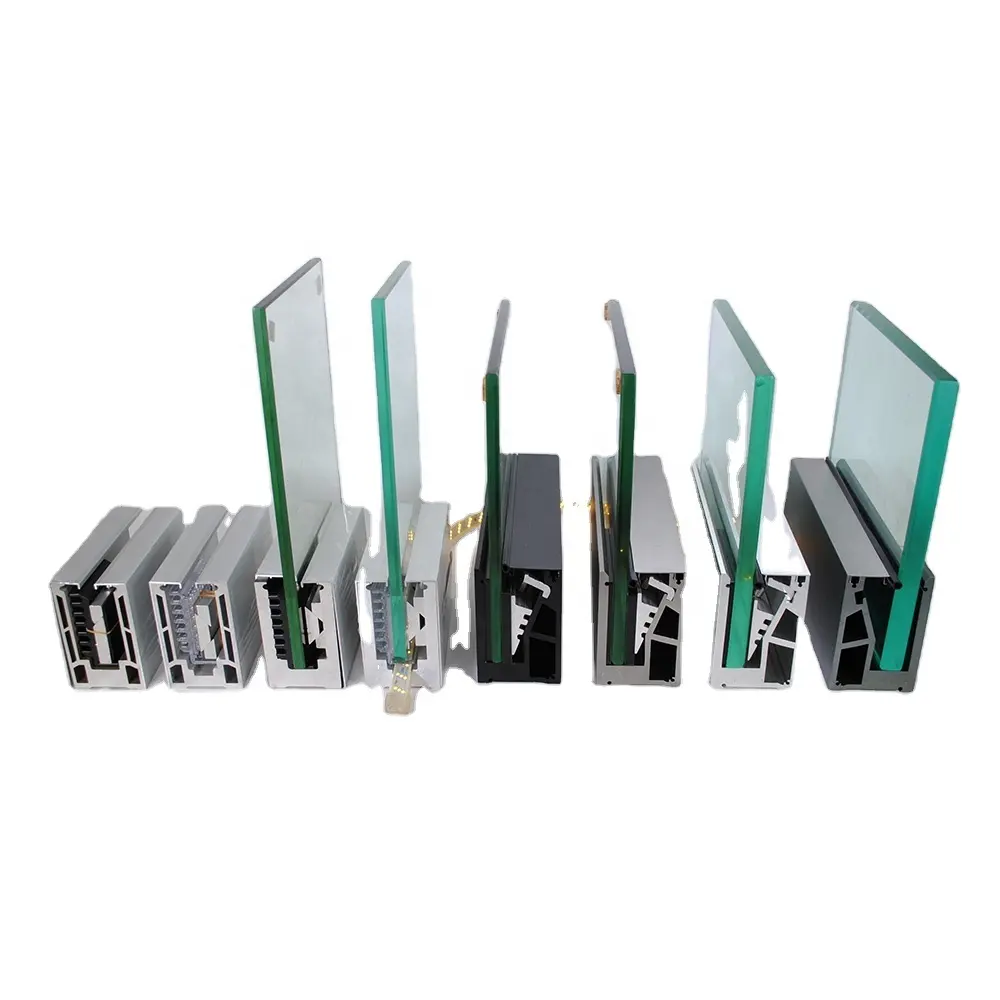

Aluminum glass clamp Glass Clip Aluminum Profile Material: 6063—T5 aviation aluminum thickened type is stronger, moisture-proof, corrosion-resistant, not easy to deform, anti-oxidation, and not easy to rust Surface treatment: metal spray...

ZHICHENGDA

Glass Clip Aluminum Profile

Your Better Glass Clip Aluminum Profile Manufacturer

Aluminum profiles have the following characteristics: Corrosion resistance: Aluminum has good corrosion resistance, especially after surface treatment (such as anodizing or powder coating), it can adapt to various environmental conditions. Lightweight and High Strength: Aluminum has a low density but relatively high strength, making it an ideal structural material that reduces the burden on buildings while ensuring sufficient support. Beautiful and elegant: Through different surface treatment processes, multiple colors and textures can be obtained to meet different design needs. Easy to process: Aluminum profiles can be extruded to create complex shapes and are easy to cut, drill, and perform other mechanical processing. Low coefficient of thermal expansion: Compared with other metals, aluminum has a smaller coefficient of thermal expansion, which means that it has better dimensional stability under temperature changes.

Copyright © 2025 Gaoyao Jinli Zhichengda Metal Products Factory All rights reserved. Privacy Policy

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.