Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Send Inquiry

USD 2000 ~ 3000

Brand:ZHICHENGDA

Min. Order:1 Ton

Model No:Industrial Aluminum Profile CNC equipment

Transportation:Ocean,Land,Air,Express

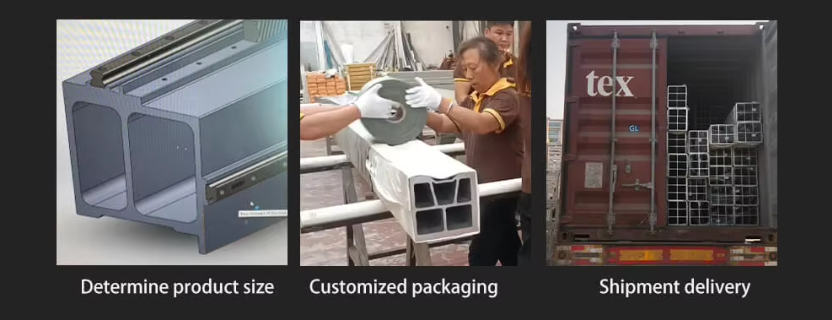

Packaging:1. Composite paper packaging. 2. Shrink film packaging. 3. Packed as your request.

Supply Ability:1500 Ton/Tons per Month

USD 2000 ~ 3000

Brand:ZHICHENGDA

Min. Order:1 Ton

Model No:aluminum profile equipment

Transportation:Ocean,Land,Air,Express

Packaging:1. Composite paper packaging. 2. Shrink film packaging. 3. Packed as your request.

Supply Ability:1500 Ton/Tons per Month

High-Quality CNC Controller: Our CNC Aviation Aluminum Gantry is equipped with a factory-supplied CNC controller, ensuring precision and accuracy in cutting operations. This advanced technology allows for efficient production and high-quality...

USD 2000 ~ 3000

Brand:ZHICHENGDA

Min. Order:1 Ton

Model No:aluminum profile equipment

Transportation:Ocean,Land,Air,Express

Packaging:1. Composite paper packaging. 2. Shrink film packaging. 3. Packed as your request.

Supply Ability:1500 Ton/Tons per Month

The use of aluminum profiles as structural components in CNC robotic arms (also known as robotic arms) has many advantages, including lightweight, high rigidity, and good processing performance. Mechanical Aluminum Profile.These characteristics make...

USD 2000 ~ 3000

Brand:ZHICHENGDA

Min. Order:1 Ton

Model No:Aluminum Alloy Extruded Profiles

Transportation:Land,Ocean,Air,Express

Packaging:1. Composite paper packaging. 2. Shrink film packaging. 3. Packed as your request.

Supply Ability:1500 Ton/Tons per Month

USD 2000 ~ 3000

Brand:ZHICHENGDA

Min. Order:1 Ton

Model No:Aluminum Extrusions Profiles

Transportation:Ocean,Land,Air,Express

Packaging:1. Composite paper packaging. 2. Shrink film packaging. 3. Packed as your request.

Supply Ability:1500 Ton/Tons per Month

Aluminum profiles for equipment refer to aluminum alloy materials used to manufacture various mechanical equipment frames, support structures, workbenches, assembly lines, etc. Mechanical Aluminum Profile. This type of aluminum profile usually has...

ZHICHENGDA

Mechanical Aluminum Profile

Your Better Mechanical Aluminum Profile Manufacturer

A variety of types and styles of aluminium extrusion profile can be customized . With diverse colors and styles, they can fulfill different types of appetite from customers.Varies of surface treatments and colors are optional , including anodized , powder coated , wood grain, electrophoresis , polished , brushed etc. We have more than 30000 moulds in stock .If our Aluminum profiles are not suitable for you, you could provide us your samples or technical drawings, we can extruded according to your designs.

Copyright © 2025 Gaoyao Jinli Zhichengda Metal Products Factory All rights reserved. Privacy Policy

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.