Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Send Inquiry

USD 2000 ~ 3000

Brand:ZHICHENGDA

Min. Order:1 Ton

Model No:Industrial Aluminum Profiles

Transportation:Ocean,Land,Air

Packaging:1. Composite paper packaging. 2. Shrink film packaging. 3. Packed as your request.

Supply Ability:1500 Ton/Tons per Month

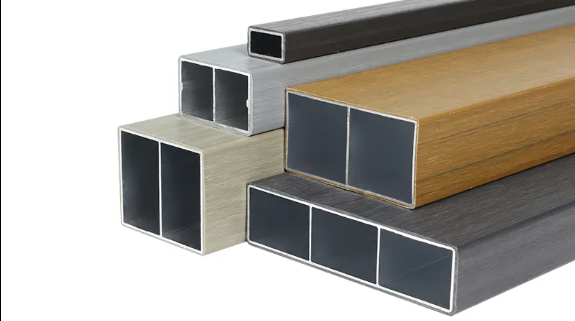

Aluminum profile for windows and doors curtain wall, fence and railing, heat sink and solar frame etc.Architectural Aluminum Profiles Industrial aluminum profile for transportation, machine building, electric and electron industry etc. (1) Product:...

USD 2000 ~ 3000

Brand:ZHICHENGDA

Min. Order:1 Ton

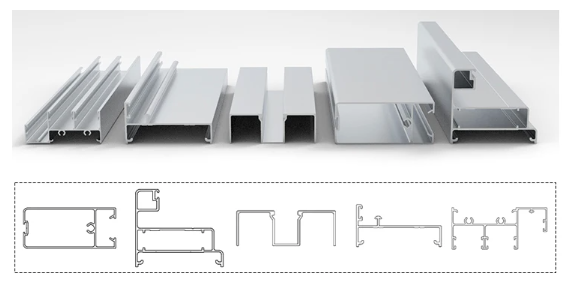

Model No:Sliding Windows Aluminum Profiles

Transportation:Ocean,Land,Air

Packaging:1. Composite paper packaging. 2. Shrink film packaging. 3. Packed as your request.

Supply Ability:1500 Ton/Tons per Month

Architectural Aluminum Profiles Specification Aluminum Extrusion product superiority : Corrosion resistance, not easy to rust, lightweight, large inventory, factory direct sales, complete mold, support customization, timely delivery, perfect...

USD 2000 ~ 3000

Brand:ZHICHENGDA

Min. Order:1 Ton

Model No:Aluminium Door Window Profiles

Transportation:Ocean,Land,Air

Packaging:1. Composite paper packaging. 2. Shrink film packaging. 3. Packed as your request.

Supply Ability:1500 Ton/Tons per Month

ZHICHENGDA Alu Factory provide CNC Machining, Welding, Bending, Punching, Drilling, Pricision any degree cutting service for Aluminium parts, all kinds of Customized aluminium parts can be produced in Reliance Alu Factory Profile Material: 6063...

USD 2000 ~ 3000

Brand:ZHICHENGDA

Min. Order:1 Ton

Model No:aluminium architectural profiles

Transportation:Ocean,Land,Air

Packaging:1. Composite paper packaging. 2. Shrink film packaging. 3. Packed as your request.

Supply Ability:1500 Ton/Tons per Month

USD 2000 ~ 3000

Brand:ZHICHENGDA

Min. Order:1 Ton

Model No:Architectural Aluminum Profile

Transportation:Land,Ocean,Air

Packaging:1. Composite paper packaging. 2. Shrink film packaging. 3. Packed as your request.

Supply Ability:1500 Ton/Tons per Month

6063 6061 t5 t6 aluminum extrusion supply aluminum extrusion profile custom extruded aluminum profile we are expert in metal fabrication and have been providing solution almost every industrial application imaginable over 10 years,specializing in...

ZHICHENGDA

Architectural Aluminum Profiles

Your Better Architectural Aluminum Profiles Manufacturer

Architectural aluminum profiles are aluminum alloy materials designed and manufactured specifically for the construction industry, widely used in various parts of buildings, from exterior walls to interior decoration. These profiles are favored for their high strength, lightweight, corrosion resistance, ease of processing, and good thermal insulation performance. The following are several common building specific aluminum profiles and their applications: Curtain wall system profiles: The curtain wall is the outer protective structure of a building, which does not bear weight but plays a protective role and beautifies the appearance. Aluminum profiles used for building curtain walls, including columns, beams, etc., must meet strict mechanical requirements to ensure safety and stability. Door and window frame profiles: Used for making various types of doors and windows, such as sliding windows, casement windows, fixed windows, folding doors, etc. These profiles need to have good sealing, waterproofing, and insulation properties to ensure the quality of indoor environment. Ceiling profiles: Ceiling aluminum profiles can be used to create modern and easy to maintain indoor spaces. Including various forms such as flat panels, grilles, and keels, suitable for commercial and residential projects. Staircase handrails and railing profiles: Provide beautiful and durable solutions while ensuring user safety. Customization can be made according to the architectural design, providing a variety of surface treatment options. Canopy and balcony fence profiles: Provide shade and shelter for outdoor areas, and increase safety. In design, drainage function and wind pressure resistance are usually considered. Louvers and sunshade system profiles: Helps regulate the amount of natural light entering the room, while also serving as a decorative element. It can be fixed or movable, providing different modes of operation. Floor profile (such as anti-skid floor strip): Used in high traffic areas or special occasions, such as entrances to public buildings, swimming pools, etc. It has anti slip characteristics, which improves the safety of pedestrians when walking. Decorative lines and accessories: Including corner lines, skirting boards, edge strips, etc., used to improve architectural details and enhance overall aesthetics. Energy saving insulation profiles: Combining efficient insulation materials to reduce heat transfer and help lower energy consumption in buildings. This is particularly important for projects pursuing green building certification. When selecting aluminum profiles specifically for construction, the following factors should be considered: Strength and stability: Ensure that the selected profile can withstand the expected load and stress. Weather resistance: Especially for exposed profiles, they should have excellent UV resistance and aging resistance. Fire rating: Select products that meet fire safety standards according to local building regulations. Processing technology: Consider installation simplicity and cost-effectiveness. Environmental performance: Prioritize the use of recyclable materials and support the concept of sustainable development.

Copyright © 2025 Gaoyao Jinli Zhichengda Metal Products Factory All rights reserved. Privacy Policy

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.